Woven Polyester Geogrids

- Introduction

- Features

- Application

- Geogrid are woven and online PVC coated, the geogrids are specifically engineered for demanding soil application. Superior grades of high tenacity, high molecular weight and low carboxyl end group polyester yarns are formed into a grid structure using a highly sophisticated weaving process and is then precision coated on line with a specially formulated polymeric compound to produce a strong, flexible, tough, dimensionally stable and durable geogrid.

- The product is ideal for the reinforcement of soils and other granular materials for a variety of applications. Geogrids are manufactured keeping in mind the new perspective for project specific reinforcement.

- High tensile strength at low elongation

- High long-term design strength

- Excellent creep resistance

- Flexible and durable

- Increased pull out resistance & compound strength

- High chemical and biological resistance

- UV resistance

- High resistance to installation damage and ease of installation.

- Cost effective

- Custom fabricated

- Block faced retaining walls

- Panel faced retaining walls

- Stabilized slopes

- Tailed gabions

- Basal reinforcement

- Track bed stabilization

PP Biaxial Geogrids

- Introduction

- Features

- Application

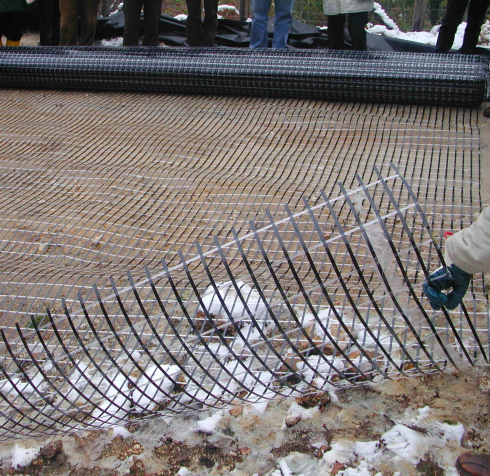

- PP Biaxial Geogrid is made of high molecular polymer through extrusion, forming and punching before MD and CD stretching. This material has considerable tensile strength in MD and CD directions.

- This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundations as a reinforcement.

- Increase the bearing capacity of the roadbed and foundation and prolong their service life.

- Prevent road surface and foundation from sinking or flawing, keep clean and beautiful ground surface.

- Convenient construction saves time and labor, reduces mounting time and decreases maintenance expenses.

- Prevent culverts from flawing.

- Enhance earth slope and prevent water loss and soil erosion.

- Decrease under layer thickness and save manufacturing cost.

- Enhance the stability of the side slope turf net patch to improve greening.

- Replace wire netting used in mine as intermediate ceiling netting.

- It can be used in all kinds of roads, railways, airports to enhance the roadbed.

- It can be used in a large car park and terminal freight yard, etc. to strengthen the foundations of a permanent load.

- It can be used in rail, road slope's protection;

- It can be used to enhance the culvert;

- It can be used as a secondary enhancement after the uniaxial geogrid soil enhancement, further enhancement to the soil; prevent soil erosion.

- It can be used in mining, tunnel reinforcement.

Non-woven Geotextiles

- Introduction

- Features

- Application

Non-Woven Geotextiles are consist of two categories:

- PET Non-Woven Geotextiles: Needle Punched Non-Woven Geotextiles made of 100% Polyester Staple Fibers which are formed into a random network for dimensional stability.

- PP Non-Woven Geotextiles: Needle Punched Non-Woven Geotextiles made of 100% Polypropylene Staple Fibers which are formed into a random network for dimensional stability.

- Excellent Tensile Strength

- Low Elongation

- Abrasion Resistance

- U. V. Stabilized

- Excellent Water Permeability

PP Multifilament Woven Geotextile

- Introduction

- Features

- Application

- Woven Geotextile is made of weaving together high strength polypropylene multifilament yarn capable of withstanding construction installation stresses.

- This material has been used to enhance the performance and reduce the cost of civil engineering projects.

- They are designed to filter soil particles from drainage systems and increase the performance life by stabilizing structure.

- Excellent Tensile Strength

- Excellent Water Permeability

- Low Elongation

- Higher Tear Resistance

- U. V. Stabilized

- Reinforcement, Filtration, Drainage and as a sand blanket

- Stabilization and Erosion Control

- Coastal and River Protection

- Reservoir Liners / Floating Covers

- Civil Engineering

- Railways and Roadways

Geocell

- Introduction

- Features

- Application

- Geocells are engineered for protection and stabilization applications. They are often used to help improve the performance of standard construction materials and erosion-control treatments.

- Geocell products are three-dimensional, expandable panels made from high-density polyethylene (HDPE), polyester or another polymer material. When expanded during installation, the interconnected strips form the walls of a flexible, three-dimensional cellular structure into which specified infill materials are placed and compacted.

- This creates a free-draining system that holds infill materials in place and prevents mass movements by providing confinement through tensile reinforcement. Cellular confinement systems improve the structural and functional behavior of soils and aggregate infill materials.

- It has the ability to expand and contract freely, and can be shrunk and folded for transportation. It can be tensioned into a net shape during construction and filled with loose materials such as soil, gravel and concrete to form a structural body with strong lateral restriction and large rigidity.

- Light, abrasion resistant, chemically stable, resistant to light and oxygen aging, acid and alkali, suitable for different soil and desert conditions.

- Higher lateral restraint and anti-slip, anti-deformation, effective enhancement of the bearing capacity of the roadbed and dispersion of the load.

- Changing the geometry of geocell height and welding distance can meet different engineering needs.

- Self-expanding, small transport volume; convenient coupling, fast construction speed.

- Erosion Control

- Ground Stabilization

- Retaining Walls

- Slope & Channel

Drainage Composite

- Introduction

- Features

- Application

- Geonet provides multidirectional continuous path for water discharge

- Anti clogging quality of nonwoven ensures consistent drainage function.

- Perfect replacement of the granular drainage layer completely or partially

- Leachate collection and leak detection system in landfills

- Roads, Rail tracks and airfields

- Parking lots, hard standages, container yard

- Factory and warehouse floors

- Landscaping and site grading works

Fiberglass Geogrid

- Introduction

- Features

- Application

- Fiberglass geogrid is a new kind of favorable earthwork base material to strengthen the road surface and road bed, which is composed of fiberglass filaments coated with an inorganic sizing agent.

- These fiberglass products possess the advantage of high tensile strength in the warp and weft directions, low elongation, excellent temperature range, and good anti-aging and alkali-resistance.

- Fiberglass geogrid is extensively used for the reinforcement of asphalt pavement, concrete pavement and roadbeds. Compared to traditional materials, fiberglass grid can reduce construction cost, extend road service and prevent deflection crack.

- Higher tensile strength for delayed reflective cracking

- Low elongation & Physical durability

- High stiffness, high modulus of elasticity, No long term creep

- Consistent chemical properties & Lower maintenance costs

- Innovative design turns crack stresses horizontally and dissipates stress

- Open aperture promotes aggregate interlock between paving courses, greatly reducing shear potential common with paving fabrics

- Ease of constructability allows for installation and immediate placement of overlaying pavement

- Airport runways and aprons

- Rigid high volume roads

- Flexible high volume roads

- Low volume roads

- Parking areas

- Surfacing of new asphalt roads pavements

- Renovation of old asphalt pavements to repair rutting or cracking

- Reinforcement of new asphalt overlays on worn out concrete roads.

Gabions

- Introduction

- Features

- Application

- Gabion is a welded mesh wire cage or box filled with materials like rocks or stone, concrete, sand, soil, and rocks. The word "Gabion" comes from the Italian word "Gabbione" which means big cage.

- Sometimes, root branches may be placed between the rock-filled cages to improve the durability and stability of the gabion. The longevity of the gabions depends on the durability of the galvanized wires. In this article, types of gabion, application, and advantages are discussed.

- Ease of handling and transportation

- Speed of construction

- Flexibility (Gabions tolerate movement)

- Permeability to water (Good drainage)

- Gabions offer an easy-to-use method for decreasing water velocity and protecting slopes from erosion.

- Construction of retaining wall structure, soil stabilization, river training, canal training, hydraulic structure.

- Gabion sacks are used in the foundation of dams.

- Prevents rock/stone falls and soil erosion protection on highways.

- It can be used as a noise barrier.

- Gabions are used as flood walls or to change the direction of the flood water streams.

- Lastly, architectural and aesthetic purposes.